Understanding Image Segmentation in Logistics

AI in logistics isn’t new. But what’s new is how precise it’s becoming. The leap from object detection to image segmentation marks the point where innovation begins to yield tangible results, both in terms of practical applications and financial returns.

Let’s break it down.

What Is Image Segmentation?

Image segmentation is the process of dividing an image into meaningful segments so that a machine can “understand” what each pixel represents.

In logistics, it means your system isn’t just detecting that a package exists—it’s identifying which part is the box, where the label is, whether there’s damage, and what kind of shape or material it’s made of.

Unlike object detection, which draws a box around an item, segmentation offers pixel-level precision —a level of detail that often requires custom AI software development tailored to logistics environments. That granularity allows machines to distinguish between a crumpled label and a damaged surface, or between two overlapping parcels on a fast-moving belt.

For operations that rely on visual inspection, this enhances accuracy and automation.

How It Works in Package Handling Context

Here’s what happens behind the scenes:

- Smart cameras capture high-resolution images of parcels in motion.

- The image segmentation model classifies every pixel in the image: label, box, background, damaged area, etc.

- This segmented image feeds into logic that makes a decision: sort it, flag it, reject it, or reroute it.

Whether it’s a barcode covered in tape, an oversized parcel hanging off a conveyor, or a box with visible dents, image segmentation enables your system to act accurately.

From Pixels to Packages: Why It’s a Game-Changer

The real power of image segmentation isn’t in the image. It’s in what you do with it.

- It reduces dependence on human inspection.

- It reduces sorting errors that result in misrouted or returned packages.

- It provides visibility into parcel quality, size, and anomalies before the package leaves the facility.

Most importantly, it turns visual data into operational decisions — especially when integrated with custom AI logistics software development that automates workflows for moving crews and warehouse teams.

For CXOs, that means faster processing, fewer mistakes, and a smarter supply chain, all driven by machines that understand more than just shapes. They understand context—and when paired with agentic AI for logistics workflows, this intelligence scales seamlessly across enterprise operations.

Turn conveyor footage into confident decisions.

Implement logistics-ready image segmentation to automate sorting, reduce manual checks, and increase throughput, without adding headcount.

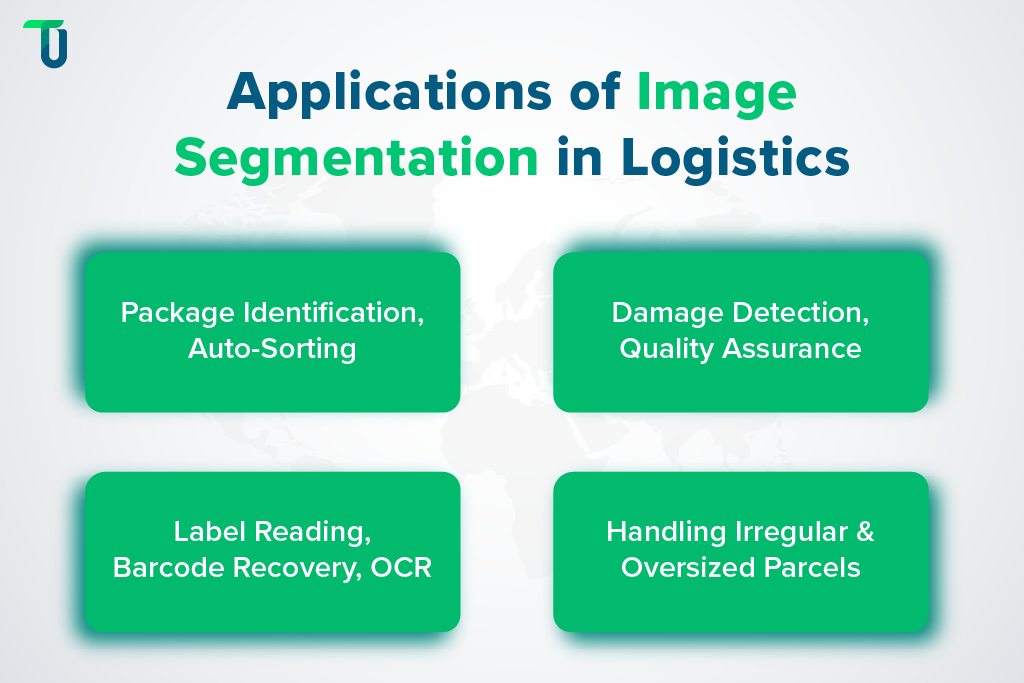

Key Use Cases of Image Segmentation in Logistics

AI delivers value only when it addresses meaningful, real-world problems. With image segmentation, the problems are right on your shop floor. From mislabeled parcels to bottlenecks at sortation lines, this technology goes beyond detection. It enables decisions that reduce friction, cost, and error.

Let’s look at the high-impact use cases where image segmentation is already delivering measurable ROI.

Package Identification and Auto-Sorting

Speed matters only when paired with precision.

Image segmentation helps your system identify each parcel with pixel-level clarity. It captures shape, size, position, and even orientation. While traditional scanners often fail when parcels overlap or tilt, AI-driven image segmentation can separate and recognize each one in the frame.

This enables:

- Fully automated sorting

- Routing decisions based on parcel dimensions or delivery priority

- Consistent processing speeds

For high-volume operations, this technology removes guesswork and reduces sortation errors at scale.

Damage Detection and Quality Assurance

One overlooked dent can lead to a return, a refund, or a bad customer review. Image segmentation turns quality control into a proactive process. It detects deformities, tears, or crushed packaging before the item is dispatched. It does not just tell you something is wrong. It shows precisely where the damage is.

Operational benefits include:

- Fewer damaged packages are leaving the facility

- Reduced returns and replacements

- Higher SLA compliance and customer satisfaction scores

This improves the effectiveness of quality checks, helping to avoid business losses.

Label Reading, Barcode Recovery, and OCR

Labels are rarely perfect. They arrive bent, smudged, or torn. While traditional barcode scanners often struggle with them or miss them, image segmentation models trained to handle such situations often perform much better.

By isolating the label area, the system improves the accuracy of OCR and barcode recognition. Even if the label is crooked or partially hidden, the model can be trained to enhance its readability using some additional steps, like super-resolution, multispectral imaging, etc.

This leads to:

- Higher first-pass scan success rates

- Fewer manual interventions for label correction

- Faster and more reliable handovers between fulfillment points

This often provides a productivity boost for warehouses with high scan volumes.

Handling Irregular and Over-Sized Parcels

Not all packages fit the standard mold. Some are round, transparent, overstuffed, or wrapped in non-uniform shapes.

Image segmentation systems can be trained to process these exceptions. It outlines precise contours and understands the real-world dimensions of odd-sized packages. This helps route, sort, and handle them.

Key benefits:

- Automation of exception-based handling

- Safer routing for fragile or misaligned items

- Better throughput and optimized lane allocation

For many operations, the toughest 15% of parcels still need human handling, AI-driven image segmentation can reduce that number.

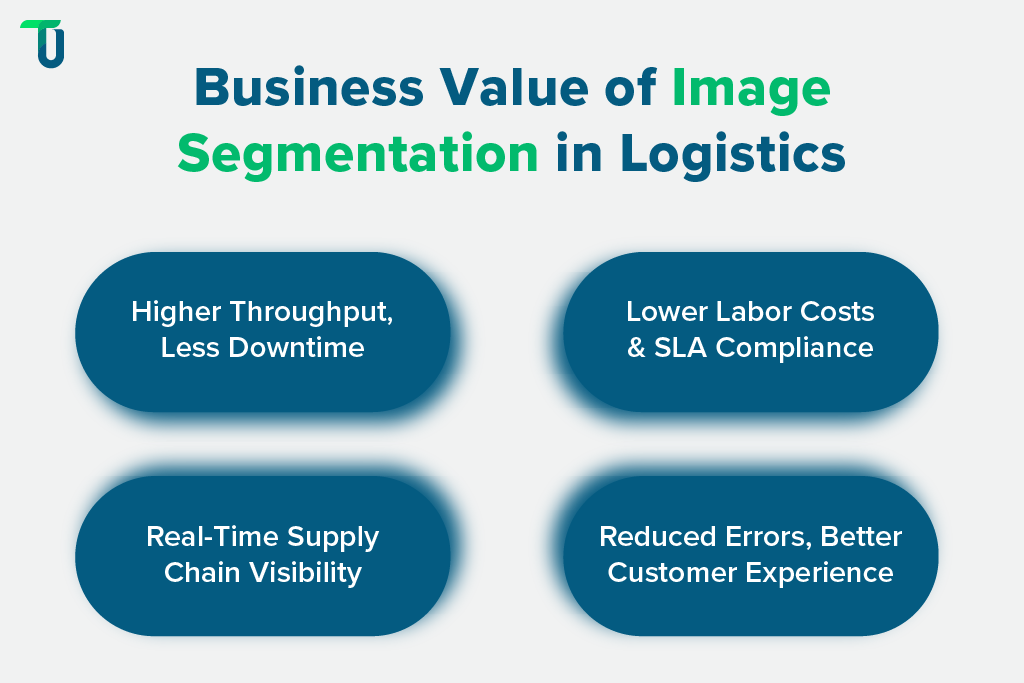

Strategic Business Value for CTOs and CEOs

AI for logistics isn’t just a tech upgrade. It is a strategic lever for growth, cost control, and operational resilience. For decision-makers, image segmentation offers more than automation. It creates a smarter, leaner supply chain that delivers measurable value.

Here is what your operation stands to gain.

Improved Throughput and Reduced Downtime

Every second saved on the line compounds into hours saved per shift. Image segmentation helps streamline sorting, routing, and inspection without slowing down the belt.

By identifying every parcel with precision, it keeps the flow moving, even during peak loads. No stoppages for manual verification. No lag from delayed damage checks.

This translates into:

- Faster order fulfillment

- Reduced equipment idle time

- Smoother handoffs across logistics nodes

Throughput improves when bottlenecks are reduced, allowing existing staff and equipment to work at peak efficiency.

Labor Cost Savings and SLA Compliance

Manual inspection teams are expensive to scale and difficult to retain. Image segmentation can automate many repetitive, visual tasks, operating continuously within the limits of system uptime and maintenance schedules.

With fewer dependencies on human QC, scanning, or sorting, your labor allocation becomes leaner and more focused on exception handling or supervision.

This results in:

- Lower staffing requirements for high-volume shifts

- Fewer SLA violations due to misroutes or processing delays

- Stronger margins, especially in fulfillment centers under cost pressure

For CXOs balancing headcount with growth, this is a direct lever to control overhead without compromising speed.

Real-Time Visibility Across the Supply Chain

Image segmentation can capture detailed visual data from each scanned parcel, not just its presence, but its condition, labeling, and other attributes, in near real time.

This visibility enables:

- Insights into package quality, count, and flow

- Alerts for damaged goods or labeling issues

- Integration with WMS, TMS, and ERP platforms

With every scan, your operation gets smarter. You go from reactive problem-solving to proactive optimization.

Lower Error Rates and Higher Customer Satisfaction

When mistakes drop, customer confidence rises. Image segmentation reduces human errors in identification, sorting, and inspection by introducing machine-led consistency.

The impact is clear:

- Fewer lost or misrouted packages

- Reduced return and complaint volumes

- Improved delivery accuracy and customer ratings

For brands that compete on service, reliability is not a differentiator. It is the expectation. This is how you meet and exceed it—at scale.

The AI Tech Stack Powering Image Segmentation in Logistics

Behind every real-time image segmentation deployment is a purpose-built tech stack that balances speed, scale, and accuracy. This isn’t about experimenting with AI. It’s about engineering intelligence into the flow of logistics.

Here is what powers the results.

Advanced Image Segmentation Models

Today’s image segmentation relies on a diverse set of deep learning approaches built for both speed and detail. Popular options include real-time families like Ultralytics’ YOLO (including YOLO11 segmentation variants) and foundation models such as Meta’s Segment Anything (SAM). YOLO-style models excel at low-latency detection and pixel-level segmentation on edge hardware, while foundation models can simplify annotation and handle zero-shot tasks. For a deeper look at the best logistics-ready computer vision tools, see how enterprises are deploying them for scale.

When trained on logistics-specific datasets, these models can detect:

- Label locations and barcode patterns

- Surface damage, material types, and packaging inconsistencies

The result is a system that not only identifies what’s in the frame but interprets it in context. With ongoing data updates and human-in-the-loop validation, accuracy can be maintained and improved over time.

Edge Computing, Smart Cameras, and Cloud Pipelines

The system is only as fast as its weakest link. That is why high-performance image segmentation relies on a hybrid infrastructure built for speed at the edge and scalability in the cloud.

- Smart cameras capture high-resolution imagery with minimal latency

- Edge devices run models close to the action, reducing dependence on network round-trips

- Cloud pipelines handle training, model updates, analytics, and system orchestration

This architecture allows logistics operations scale while keeping latency low and reliability high.

Integrating with ERP, WMS, and TMS Platforms

AI is only valuable when it fits into the existing enterprise ecosystem. The best image segmentation deployments do not work in isolation. They integrate directly with platforms like AI-powered Warehouse Management Systems, TMS, and ERP tools.

- Warehouse Management Systems (WMS)

- Transportation Management Systems (TMS)

- Enterprise Resource Planning (ERP) tools

This tight integration ensures that every detection event, quality flag, or route adjustment becomes actionable within your core systems. From label scan to route change, the handoff is seamless.

For CTOs leading modernization, this reduces technical debt and accelerates time to value without needing a full-stack overhaul.

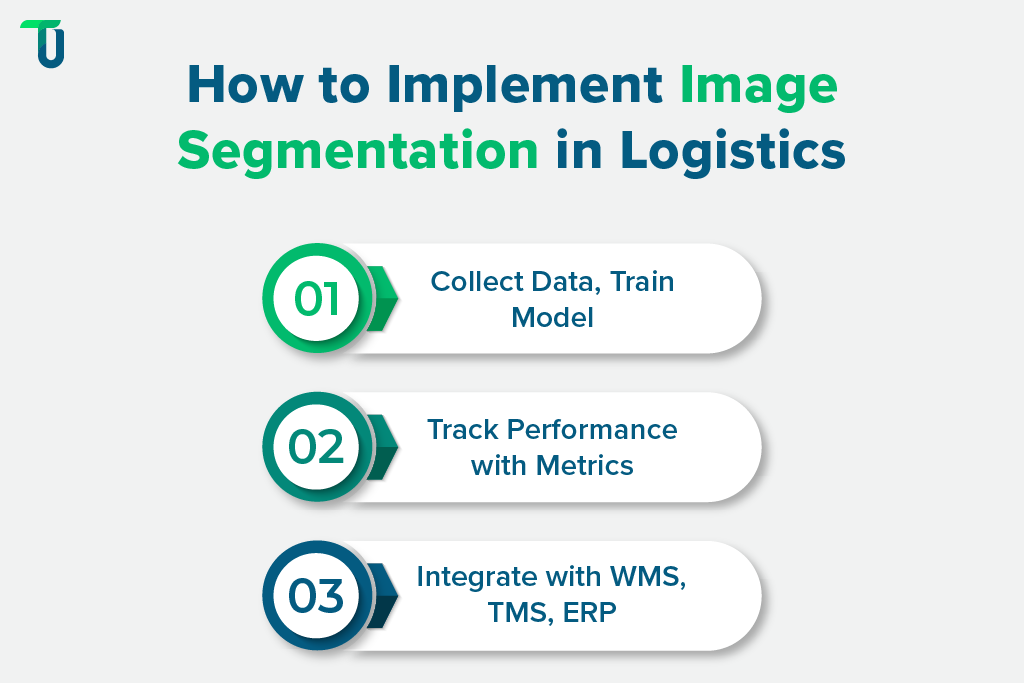

Implementation Strategy: From Pilot to Scalable Rollout

Deploying image segmentation in logistics isn't a plug-and-play exercise. Success lies in the strategy—starting small, proving value, and scaling with control. Whether you're running a single warehouse or managing a global network, the rollout needs to be structured around three core pillars: data, performance, and integration.

Here’s how to get it right from the ground up.

Dataset Collection and Custom Model Training

Pre-trained models are a good starting point, but your warehouse is not a textbook case. The accuracy of image segmentation depends heavily on the quality and diversity of the training data.

Start by collecting visual data from your own environment:

- Real parcel images across sizes, shapes, and materials

- Labels in varying positions, lighting conditions, and print quality

- Edge cases such as damaged, irregular, or transparent packaging

This dataset becomes the foundation for custom model training. With each iteration, the model becomes more attuned to your real-world logistics flow. And that directly translates into better predictions, fewer errors, and smarter automation. This is why many teams complement custom training with logistics-ready computer vision tools that provide faster deployment and proven scalability.

Performance Metrics to Track at Each Stage

Running a pilot without the right metrics is like flying blind. To justify scale, you need clear KPIs tied to business impact.

Track metrics such as:

- Intersection over Union (IoU) for segmentation accuracy

- Inference latency to ensure real-time performance

- First-pass success rate for scans and parcel classification

- Error rate reduction compared to manual baselines

- Impact on throughput, SLA compliance, and labor hours

These metrics not only validate ROI but also uncover improvement opportunities as your enterprise-level image recognition system scales.

Integration Considerations for Enterprise Systems

A high-performing model is not enough. It needs to work within your enterprise architecture, not around it.

Plan integrations with:

- WMS for real-time parcel tracking and status updates

- TMS for dynamic routing and load planning

- ERP for cost tracking, SLA reporting, and performance benchmarking

Use APIs, edge gateways, or middleware that ensure seamless data flow across systems. This allows your AI insights to trigger automated actions—not just deliver dashboards. The goal is not to build a standalone AI project. It is to embed intelligence into your existing logistics engine with minimal disruption and maximum visibility. You could also use agentic AI for logistics workflows that connect perception with action.

For a deeper dive into how to build vision systems that are trained on your data, designed for your environment, and tuned to your business outcomes, explore this guide on deploying enterprise computer vision from scratch.

At TenUp Software Services, we approach implementation as a structured, end-to-end journey. Our team starts with a clear understanding of your business goals and operational environment to develop high-quality training datasets, run agile pilots, and validate early-stage models in real-world conditions.

We don’t stop at proof of concept. With deep expertise in AI engineering, DevOps, and data pipelines, TenUp builds robust, production-ready systems designed for performance, reliability, and scale. Our DataOps practices ensure clean, annotated, and continuously evolving datasets, while our cloud and edge deployment capabilities enable flexible, location-aware inference across geographies.

Pitfalls in Scaling Image Segmentation (And How to Avoid Them)

Deploying image segmentation at scale sounds impressive on paper. But the real battle? Navigating the operational and compliance minefield. Here’s what you need to get right:

Pitfall 1: Weak Infrastructure and Unstructured Data

Most enterprises jump into image segmentation without prepping their infrastructure. The result? Laggy performance, inaccurate detections, and model failure in production. If your edge devices aren’t fast enough or your training datasets are messy, scaling becomes a bottleneck.

How to Avoid It:

- Audit your edge devices and cloud pipelines early

- Use AI-optimized hardware

- Clean, annotate, and standardize your datasets before model training

- Pilot test across different environments to ensure infrastructure resilience

Pitfall 2: Skipping the Data Privacy and Compliance Check

Scaling image segmentation often means ingesting massive volumes of visual data. But if you're operating across regions, that data is likely subject to GDPR, HIPAA, or local privacy laws. Many companies overlook this until it becomes a legal issue.

How to Avoid It:

- Embed compliance checks into your data pipelines

- Use edge computing to anonymize or redact sensitive visuals before cloud upload

- Partner with vendors who offer region-specific data storage and handling policies

- Regularly audit for compliance breaches, especially when retraining models

Pitfall 3: Model Drift and Accuracy Loss Over Time

Even the best segmentation models degrade. Lighting changes, new packaging formats, or seasonal product lines can cause a sharp drop in model accuracy. This drift usually goes unnoticed until it affects ROI.

How to Avoid It:

- Implement continuous monitoring of model performance

- Set up real-time feedback loops from production environments

- Retrain models periodically using updated datasets

- Use tools like MLflow or ClearML for experiment tracking and versioning

Is Your Logistics Operation Ready for Image Segmentation?

Most logistics leaders understand the promise of AI, but few are prepared for what it takes to implement image segmentation effectively. It's not just about deploying a smart camera or feeding data into a model. It’s about ensuring your operation has the right infrastructure, data pipeline, team alignment, and compliance foundation to support the shift.

Before you invest time and resources, evaluate your current state against these readiness indicators.

Core Indicators of Readiness

- You have high-resolution visual data at scale

No high-quality visual data, no reliable model. You need a consistent stream of images or videos from drones, conveyors, forklifts, or smart shelves to fuel your models.

- Your storage and compute environment can scale

Segmentation models demand powerful processing. If your setup lacks GPU-accelerated infrastructure or cloud-based scaling, bottlenecks are inevitable.

-

You’ve identified the business outcome you want to improve

AI should solve a clear operational pain point. Whether it’s reducing sorting errors, accelerating dispatch, or improving damage detection, the ROI must be measurable.

-

Your data is clean, labeled, and accessible

Model performance depends on the quality of training data you’ve used. If your visual data is scattered or unstructured, it will compromise outcomes from day one.

A Readiness Checklist for CTOs and Innovation Leads

Use this checklist to gauge whether your logistics environment is ready for image segmentation at scale:

- Real-time visual feeds from key checkpoints

- Annotated datasets or a defined labeling strategy

- Cloud or hybrid infrastructure with GPU capability

- Edge devices to reduce latency in time-critical zones

- Data governance in place for visual capture

- In-house AI talent or access to implementation partners

- Business case aligned with efficiency, accuracy, or cost goals

If two or more are missing, it’s worth pausing. A half-ready foundation will only lead to pilot fatigue and missed expectations.

Build vs Buy: Making the Right Investment Call

This is where strategic clarity matters. Should you build a custom image segmentation model or integrate an off-the-shelf solution?

Build If:

- Your use case is highly specific, such as segmenting damaged cartons on irregular pallets,

- You have access to a skilled ML team and enough budget for continuous model iteration,

- Data privacy and full control are non-negotiables—making custom AI software development a stronger strategic fit.

Buy If:

- You need quick deployment across multiple warehouses

- Your goals align with common logistics use cases (object tracking, barcode visibility, etc.)

- You are in the pilot or validation stage of AI adoption

Decision Tip: Prioritize flexibility. Even pre-built tools should allow you to customize later. Locking into rigid systems too early will create limitations as your needs evolve.

Vision AI, Delivered with Precision: Why Logistics Leaders Trust TenUp

In logistics, accuracy and speed aren’t optional. They are operational imperatives. TenUp Software Services brings domain-specific computer vision expertise to help logistics leaders automate inspections, inventory tracking, and damage detection at scale.

Logistics-Tailored Vision AI

We engineer precision-driven image segmentation models built for fast-moving supply chains. These models are optimized for edge, cloud, and hybrid environments.

Production-Grade Deployments

Our AI solutions go beyond demos. We design, test, and deploy models that perform in real-world warehouse and transit conditions.

Clean Data. Clean Results.

From polygonal annotations to data versioning, TenUp ensures every pixel and label serves a purpose. This drives more accurate detections and reduces false positives.

Scalable and Secure Integration

Whether it’s SAP, TMS, or custom software, our AI integrates seamlessly into your existing stack. We prioritize enterprise-grade security and governance at every step.

TenUp Software Services helps logistics teams turn Vision AI into real operational wins, with the precision and reliability of today's supply chain demand.

Ready to Make Every Pixel Count?

Build and scale logistics-ready Vision AI solutions that deliver real-time insights, reduce manual effort, and optimize operations.

Frequently asked questions

What’s the difference between object detection and image segmentation in logistics?

Object detection draws a bounding box to locate parcels, while image segmentation labels every pixel, capturing labels, shapes, and defects. Object detection tells you what and where, but image segmentation shows exactly how it looks, making it more accurate for sorting, damage checks, and automation.

How does image segmentation improve SLA compliance in logistics?

Image segmentation enables real-time quality checks by spotting defects, mislabels, and damages before dispatch. By reducing errors and delays, it ensures shipments meet SLA commitments on speed, accuracy, and delivery conditions.

Can image segmentation handle irregular or non-standard packages?

Yes. Unlike traditional scanners, image segmentation outlines precise parcel contours, making it effective for oversized, round, transparent, or misshaped items. By understanding exact shapes and dimensions, it reduces errors in sorting and routing while minimizing manual exception handling in logistics.

How does image segmentation integrate with ERP, WMS, and TMS systems?

Image segmentation connects through APIs to ERP, WMS, and TMS platforms, feeding parcel data like status, dimensions, or damage. This automates updates, triggers routing workflows, and ensures real-time visibility across the supply chain.

What metrics should CXOs track to measure image segmentation ROI?

CXOs should track IoU accuracy, error reduction rate, throughput gains, and first-pass scan success. Business KPIs like SLA compliance, labor cost savings, and faster order fulfillment link technical performance to measurable ROI in logistics.

What are the biggest risks of scaling image segmentation in logistics?

Key risks include poor data quality, model drift, high GPU and infrastructure costs, and compliance issues with visual data. Without proactive monitoring and retraining, accuracy drops and costs rise. Strong governance and continuous updates are critical to scaling safely.

Can AI image segmentation replace human quality inspectors?

No. Image segmentation excels at automating routine checks like label reading, defect spotting, and damage detection. But human inspectors are vital for complex exceptions, judgment, and governance. The most effective approach is a hybrid workflow where AI handles volume and humans ensure oversight.

How does image segmentation contribute to sustainable logistics?

Image segmentation reduces misrouted parcels, failed deliveries, and unnecessary returns, cutting transport waste, packaging waste, and carbon emissions. By improving accuracy in sorting and routing, it supports greener supply chains and more efficient resource use.